Timber vs Concrete vs Steel - A Comparison For Buildings

Timber vs Concrete vs Steel - A Comparison For Buildings

Timber, steel, and concrete are three of the most commonly used materials in construction. Each has its unique properties, advantages, and disadvantages, making them suitable for different applications.

|

|

|

Summary

The following table is a compressed summary of considerations of these materials for building designers.

| Advantages | Disadvantages | |

|---|---|---|

| Timber |

Renewable resource: Timber is a sustainable material when sourced responsibly. Insulating properties: It provides excellent thermal and acoustic insulation. Aesthetics: Timber offers a natural and warm appearance. Lightweight: Compared to steel and concrete, timber is relatively lightweight. |

Susceptible to fire and decay: Without proper treatment, timber can be prone to fire and rot. May require maintenance: Regular inspections and treatments are necessary to maintain its integrity. Limited load-bearing capacity: For large structures, timber may not be as strong as steel or concrete. |

| Concrete |

High compressive strength: Concrete is excellent for bearing heavy loads. Fire-resistant: It can withstand high temperatures. Durable: Concrete structures can last for centuries. Versatility: It can be used in a wide range of applications, from foundations to high-rise buildings. |

Low tensile strength: Concrete is weak in tension and may require reinforcement with steel. Shrinkage and cracking: Concrete can shrink and crack over time. High carbon footprint: The production of cement contributes to greenhouse gas emissions. Heavyweight: Concrete structures can be heavy, which may increase construction costs. |

| Steel |

High strength-to-weight ratio: Steel is strong and can support heavy loads. Ductile: It can be easily shaped and formed into various structures. Fire-resistant: Steel can withstand high temperatures. Long lifespan: With proper maintenance, steel structures can last for decades. |

Susceptible to corrosion: Steel can rust if not protected from moisture. Requires fireproofing: In certain applications, steel may need to be fireproofed to prevent collapse. High initial cost: The production and fabrication of steel can be expensive. |

Structural Considerations

As the primary purpose of these materials is to support the building structure, we have a more detailed look at the main differences from a structural perspective below.

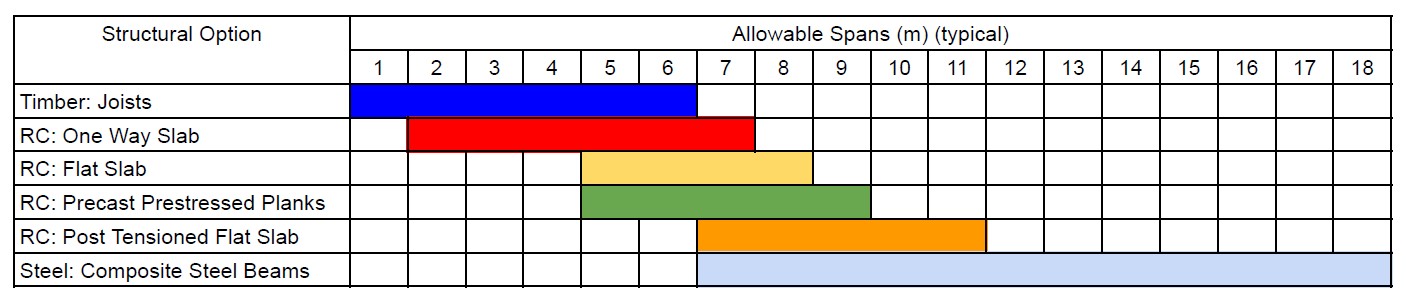

As you might expect, the capacity of different materials to carry load is broadly related to its density or weight. You would therefore expected spans of each material would increase from Timber -> Concrete -> Steel.

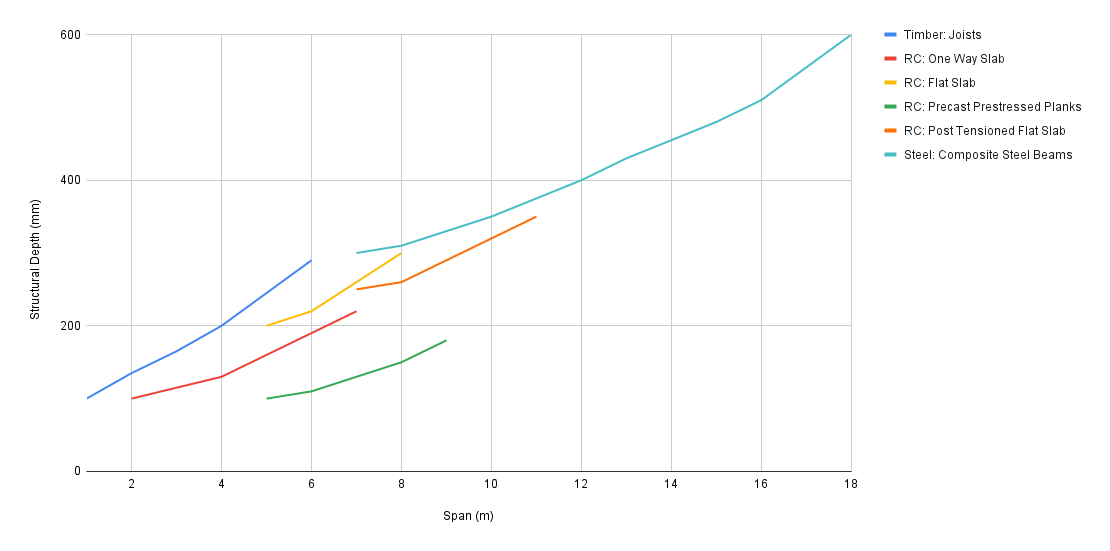

This can be seen in the Allowable Spans for some different structural systems in the chart below:

Depth required to achieve those spans is a main design consideration for all building designers.

Typical Structural Floor Depth vs Span can be seen in the chart below which effectively summarises of a large part of Structural Engineering in one image:

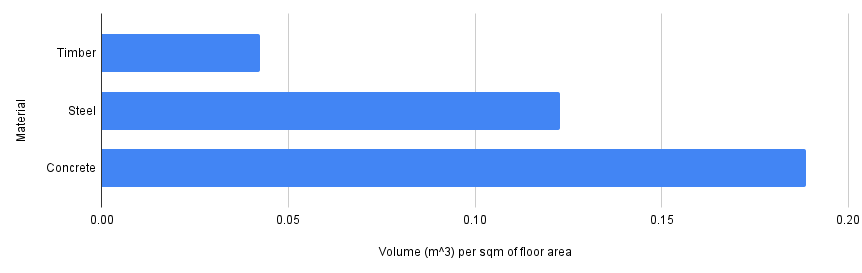

Material volume does not have a simplistic relationship to density like span does. Concrete often requires the most material, timber the least and steel in between. This is partly due to the relative weight of mass concrete but also the way it needs to be used to build effectively.

For a simple rectangular building we found the results in the chart below

Certain materials are more readily avalable in particular areas. Some regions have a preference for or may not have the skilled workforce for certain types of construction.

Aside from the purely strength related properties, often a choice of structural material will be influenced by the builder. They will have a preference for certain types of construction based on complexity and cost to construct. For example, in-situ concrete is well known to require a large workforce that also needs to be on site, whereas Mass Timber requires very few builders on site with most of the parts only requiring screw and bolt fixing to complete the built form.

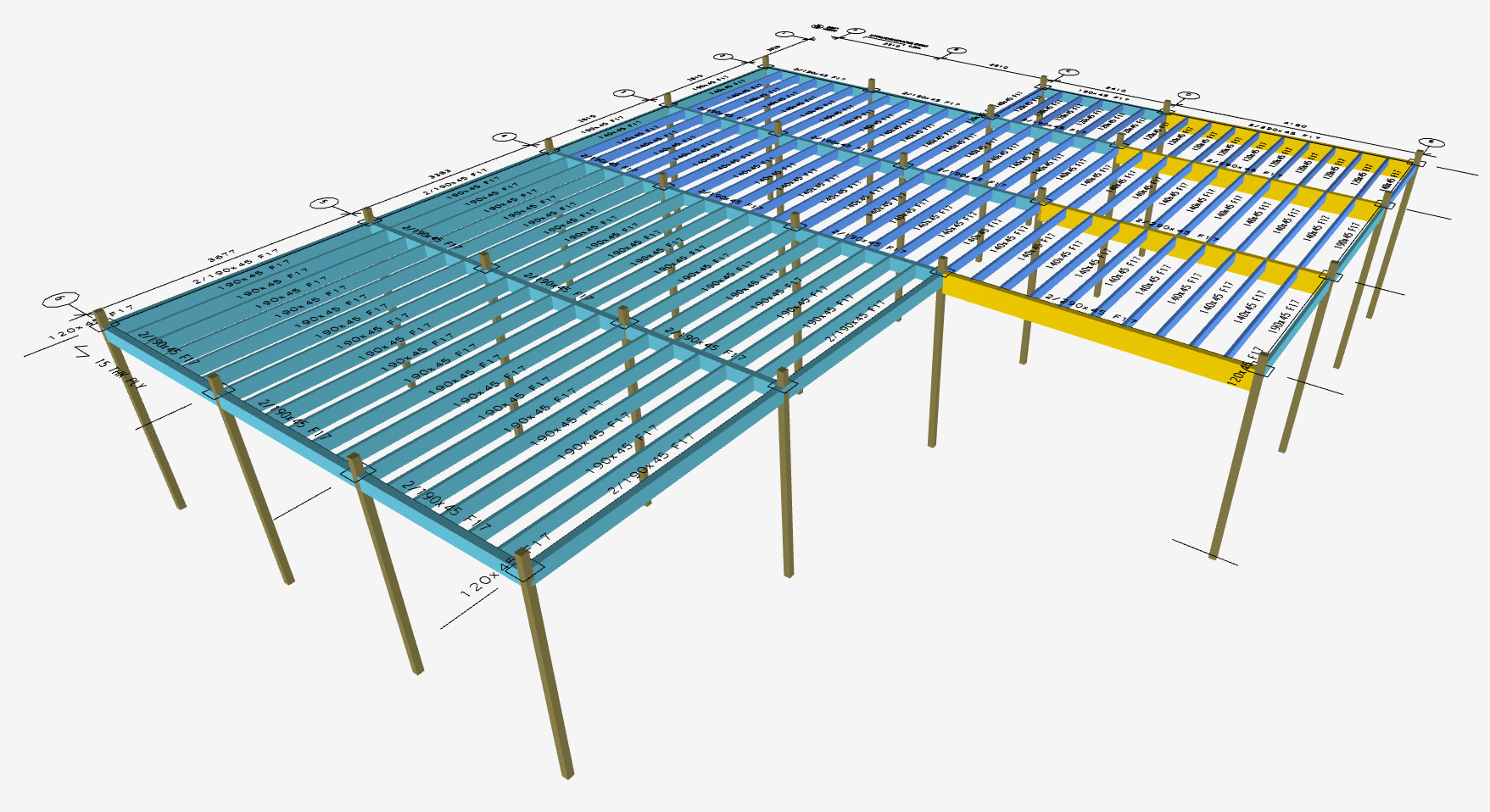

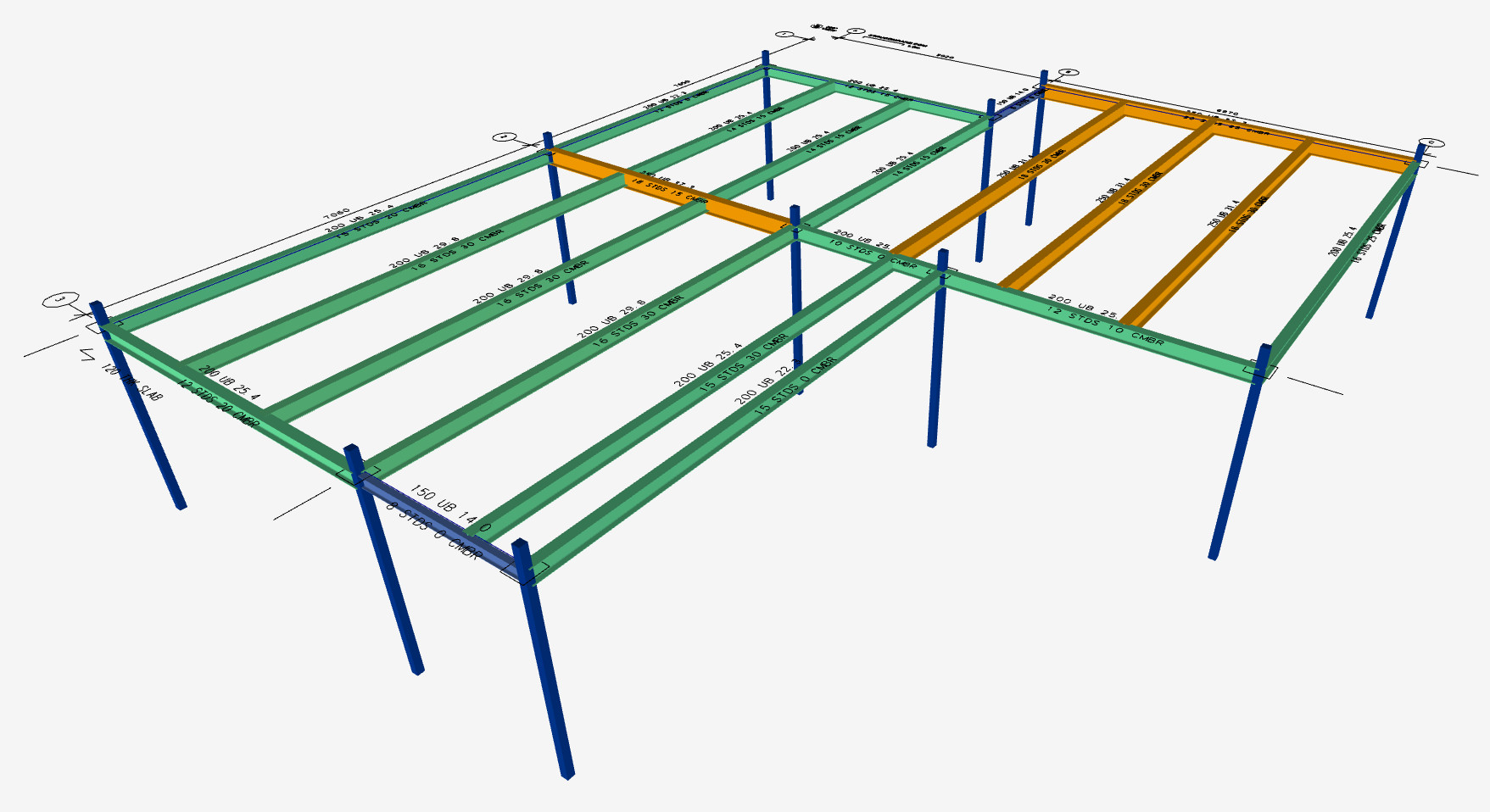

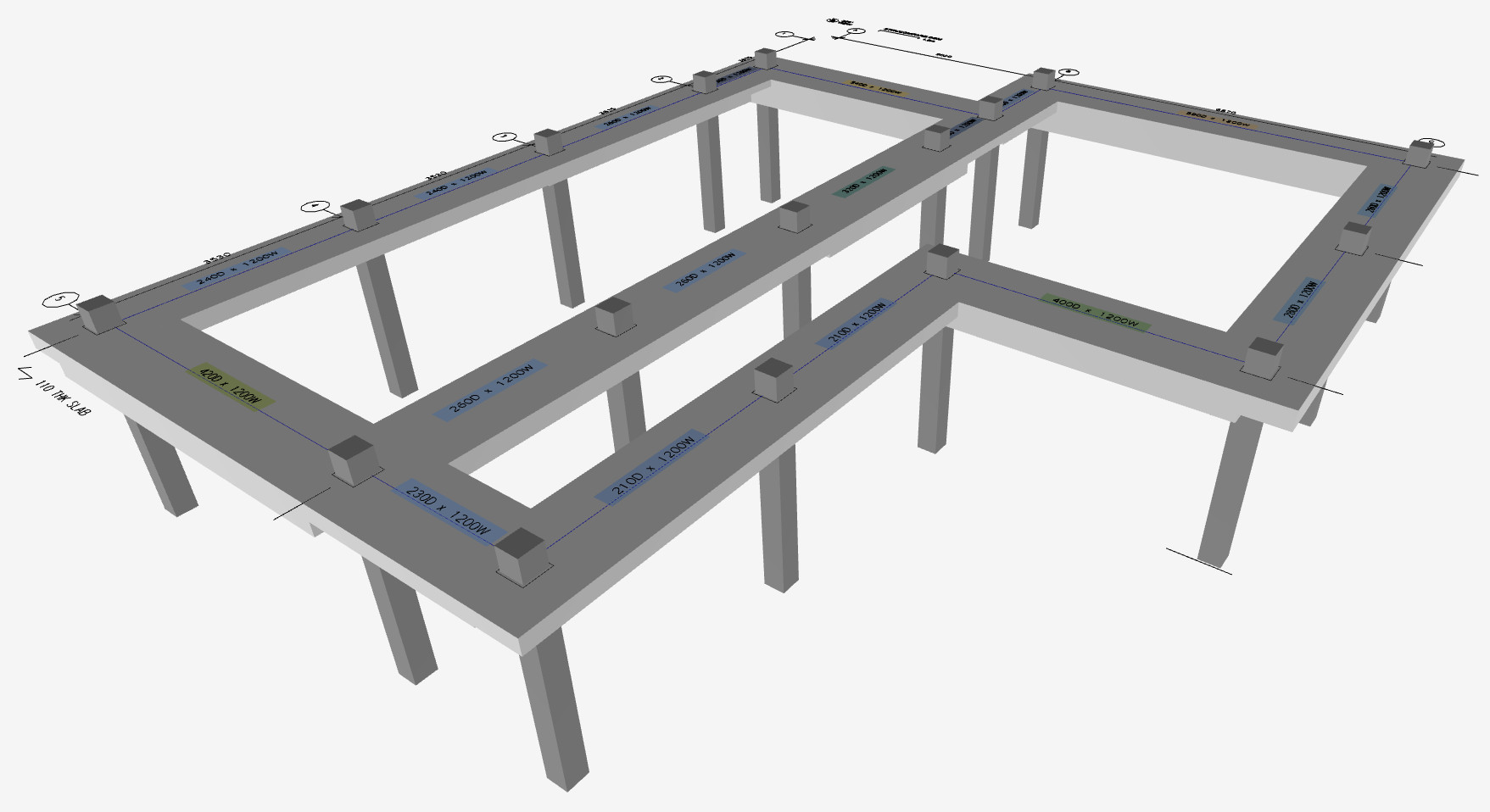

Compare Designs in Real Time

Get beam designs for each material in your browser at StruCompare. This includes full floor beam layouts, column locations, structural depth and material volumes.

At www.StruCompare.com you can instantly access a range of preliminary structural solutions for your building.